13.3

Impact Factor

Theranostics 2023; 13(1):161-196. doi:10.7150/thno.79639 This issue Cite

Review

Recent advances in the medical applications of hemostatic materials

1. Department of the General Surgery, Jilin University Second Hospital, Changchun, China.

2. Department of Operating Theater and Anesthesiology, Jilin University Second Hospital, Changchun, China.

3. Department of the Dermatology, Jilin University Second Hospital, Changchun, China.

* Equally contributed to this work.

Received 2022-10-7; Accepted 2022-11-14; Published 2023-1-1

Abstract

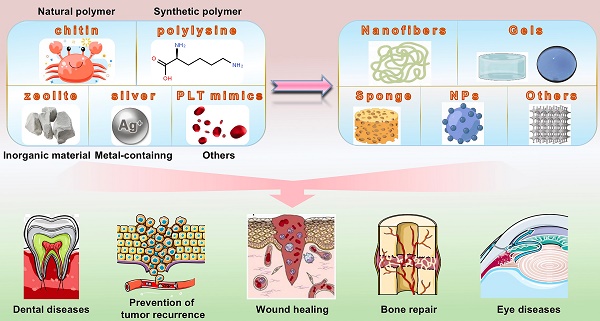

Bleeding caused by trauma or surgery is a serious health problem, and uncontrollable bleeding can result in death. Therefore, developing safe, effective, and convenient hemostatic materials is important. Active hemostatic agents currently used to investigate the field of hemostasis are divided into four broad categories: natural polymers, synthetic polymers, inorganic materials, and metal-containing materials. Hemostatic materials are prepared in various forms for wound care applications based on the active ingredients used. These materials include nanofibers, gels, sponges, and nanoparticles. Hemostatic materials find their applications in the field of wound care, and they are also used for hemostasis during malignant tumor surgery. Prompt and effective hemostasis can reduce the possibility of the spread of tumor cells with blood. This review discusses the outcomes of current research conducted in the field and the problems persisting in the field of developing hemostatic materials. The review also presents a platform for the further development of hemostatic materials. Bleeding caused by trauma or surgery is a serious health problem, and uncontrollable bleeding can result in death. Therefore, developing safe, effective, and convenient hemostatic materials is important. Active hemostatic agents currently used to investigate the field of hemostasis are divided into four broad categories: natural polymers, synthetic polymers, inorganic materials, and metal-containing materials. Hemostatic materials are prepared in various forms for wound care applications based on the active ingredients used. These materials include nanofibers, gels, sponges, and nanoparticles. Hemostatic materials find their applications in the field of wound care, and they are also used for hemostasis during malignant tumor surgery. Prompt and effective hemostasis can reduce the possibility of the spread of tumor cells with blood. This review discusses the outcomes of current research conducted in the field and the problems persisting in the field of developing hemostatic materials. The review also presents a platform for the further development of hemostatic materials.

Keywords: hemostatic materials, polymer, nanofibers, hydrogels, medical use.

Introduction

Post-traumatic hemorrhage is the second leading cause of human trauma-related deaths, accounting for 15% of all trauma deaths [1, 2]. The amount of blood in a normal person remains relatively constant during the life of the person, and the blood volume is proportional to the person's body weight. The amount of blood in a normal human has been reported to be approximately 7-8% of the total body weight [3]. When blood loss reaches 20% of total blood volume, it becomes difficult to maintain normal blood volume and blood pressure. Symptoms such as dizziness and reduced urine output are observed under these conditions. When the extent of blood loss exceeds 40% in a short time, life-threatening conditions develop if blood is not transfused in time [4]. Therefore, it is important to control the extent of bleeding. Cessation of bleeding from small wounds is realized through a series of events such as vasoconstriction, platelet thrombosis, and blood clotting [5].

The rupture of blood vessels can result in vasoconstriction, reducing blood flow to the injured site. At the same time, some hemostatic agents, such as thromboxane, are released into the bloodstream. These promote the local constriction of small arteries [6]. Injury exposes subendothelial collagen and a small number of platelets adhering to the damaged endothelium. The release of adenosine diphosphate (ADP) from erythrocytes and thrombin generated during coagulation can trigger the induction of the functions of platelets. The activated platelets promote the release of endogenous ADP and thromboxane 2 (TXA2), resulting in the activation and recruitment of a large number of platelets. This results in the formation of platelet thrombi that plug wounds, and the process is known as primary hemostasis [7]. The process of coagulation cascade can activate multiple coagulation factors in a certain sequence following two pathways (endogenous and exogenous). Eventually, soluble fibrinogen in plasma is converted into insoluble fibrin, which interweaves to reinforce the hemostatic plug. The endogenous coagulation pathway is initiated by the activation of a surface factor (Factor XII) by damaged endothelial cells, whereas the exogenous coagulation pathway is activated following the exposure of a tissue factor (Factor III) to blood. The two pathways converge by activating the respective downstream coagulation factors. This results in the activation of the Stuart Prower factor (Factor X) pathway, which activates thrombinogen. Thrombin could activate the fibrin stabilizing factor (Factor XIII), which, in the presence of Ca2+, could cause the fibrin monomers to polymerize with each other, resulting in the formation of water-insoluble multimeric clots. The platelet emboli formed during the primary hemostasis phase are reinforced under these conditions [8, 9]. Under normal circumstances, rapid hemostasis can be achieved in the presence of a large number of local adherent platelets and clotting factors. Thrombotic disorders are observed when the number of platelets increases beyond a certain range [10]. However, severe post-traumatic bleeding requires aggressive human intervention to promote coagulation. Uncontrolled post-traumatic hemorrhage is one of the leading causes of preventable death. Massive blood loss can sometimes lead to unavoidable serious complications requiring amputation. Severe infection may also occur [11].

It is important to develop safe, efficient, and stable hemostatic materials urgently. Hemostatic materials can be used to stop bleeding, and the process is realized following various ways. For example, gauze, a traditional hemostatic material, can be used to stop bleeding under conditions of physical compression (realized using pressure wraps) [12]. Hemostatic sponges function as efficient absorbents. These swell when local blood gets absorbed, resulting in local compression. Polyurethane (PU) sponges, which are used for local compression, are used as nasal tamponades [13]. Several hemostatic materials can activate the hemostatic pathways in the human body in various ways. For example, chitosan sponges can promote hemostasis by activating and aggregating platelets exploiting the negative charges on the chitosan surface [14]. At the same time, the absorbent property of the sponge helps increase the local concentration of platelets and coagulation factors in the wound. This results in the promotion of the coagulation cascade. Several hemostatic materials can also be loaded with hemostatic drugs. It has been observed that the thrombin-loaded gelatin sponges that have been used to study a porcine liver hemorrhage model can be used to achieve excellent hemostasis [15]. Nanofibers have been found to be excellent drug carriers, and these can be used to stop bleeding and promote the process of wound healing [16, 17]. There are many commercially available hemostatic materials, such as Hemcon® (chitosan-based), TraumaDEX® (Potato starch-based microparticles), and QuickClot® (zeolite-based), which can efficiently reduce the bleeding time to a certain extent. These agents exhibit antimicrobial activity but also suffer from poor biodegradability. These cannot be used to treat complex wounds and are difficult to remove.

Natural polymers, synthetic polymers, inorganic materials, and metal-containing materials are primarily used to realize hemostasis (Table 1). Natural polymers used in the field of medicine for hemostasis include chitosan, cellulose, hyaluronic acid (HA), alginate, collagen, and fibrin. Peptides, polyethylene glycol (PEG), polyurethane (PU), polyvinyl alcohol (PVA), polycaprolactone (PCL), and poly (ethylene oxide) (PEO) are used to prepare the synthetic hemostatic materials. Most studies on inorganic hemostatic materials have focused on zeolites, mesoporous silica, and graphene. Calcium, zinc, and silver are primarily used to prepare metal-containing hemostatic materials. It is challenging to process these materials containing different types of active ingredients and develop different chemically modified hemostatic materials that exhibit powerful wound healing properties in addition to the basic hemostatic properties. The type of hemostatic material is strongly related to its function. Nanocellulose, hydrogels, nanoparticles, etc., are widely used for the development of hemostatic materials. Chitosan hydrogels, chitosan nanoparticles, and chitosan hemostatic sponges, which can be used efficiently to treat a wide range of wounds, are different types of chitosan-based hemostatic materials. Hemostatic materials in the form of hydrogels tend to promote clotting by thickening the blood and increasing the concentration of platelets and clotting factors. These materials exert a local compression effect by expanding in size after absorbing water. However, hydrogels are notoriously difficult to remove and cannot be efficiently used to treat complex, deep wounds. Nanoparticles can be used effectively to realize the hemostasis of deep and irregular wounds. However, these are difficult to remove. Different forms of hemostatic materials prepared using the same active ingredient can be used to treat different types of wounds. For example, Hemcon® and Chitoflex® are lyophilized chitosan-based materials used to treat post-traumatic or surgical bleeding. It should be noted that Chitoflex® is more flexible than Hemcon®, and the former is more suitable than the latter to stop bleeding occurring near joints. The composite material is strong and suitable for treating complex and diverse wounds.

This review presents the mechanisms through which different substances promote coagulation. We also present the results obtained when various nanomaterial-based hemostatic materials were studied. Finally, we have focused on the pros and cons of the diverse forms of hemostatic materials and have reported the application prospects and importance of hemostatic materials in the field of healthcare. The data presented herein provide an outlook for future research directions.

Chemical composition of hemostatic materials

Natural polymers, synthetic polymers, inorganic materials, and metal-containing materials are currently used to prepare hemostatic materials. In this section, we present the mechanisms following which these substances accelerate wound hemostasis.

Natural polymers

The widely available natural polymeric hemostatic materials currently in use are polysaccharides and collagens. Polysaccharides exhibit excellent properties. These are non-toxic to human tissues. These are non-irritants, non-immunogenic, non-hemolytic, histocompatible, and naturally degradable. These materials are widely used to manufacture artificial skin [45, 46], absorbable sutures [47, 48], and drug carriers [49-51]. Well-studied polysaccharide-based hemostatic materials include chitosan, cellulose, HA, and alginate.

Chitosan is a natural polysaccharide extracted from the shells of crustaceans. Chitosan can increase the intracellular calcium ion concentration of platelets, facilitating platelet aggregation and mutual adhesion [52]. Activation of platelets results in the production of a large number of negatively charged phosphatidylserine units on the surface, which can interact electrostatically with positively charged chitosan, increasing the viscosity of platelets. This results in the rapid formation of thrombi. The positive charge on the surface of chitosan polymers interacts with receptors containing neuraminic acid residues (negative charge) on the surface of red blood cells to promote aggregation [53]. Chitosan is abundant in nature and can be modified to improve hemostatic effects and increase the application prospects of chitosan-based materials. The cationic properties of chitosan significantly influence the function of the material as a coagulant of red blood cells and platelets. Tan et al. reacted N,N,N-trimethyl chitosan with chloroacetyl chloride to obtain chitosan derivatives. Subsequently, they reacted tricyclohexylphosphine with triphenylphosphine to obtain highly cationic chitosan derivatives [54]. The introduction of quaternary ammonium groups into chitosan improved the blood cell adhesion and antibacterial properties of the material [55]. Wibel et al. formulated thiol chitosan by incorporating L-cysteine with amide bonds. This helped improve the mucosal adhesion and penetration ability of the materials [56]. Jayakumar et al. synthesized phosphorylated chitosan by grafting mono(2-methacryloyloxyethyl) ester of phosphoric acid into chitosan to improve the stability and antimicrobial properties of the materials [57]. In addition to direct modification, Schnurch et al. grafted ethylenediaminetetraacetic acid (EDTA) onto chitosan polymers. The chelation of magnesium ions resulted in the generation of antimicrobial effects [58]. Alkylated chitosan units are hydrophobic, and these can be inserted into blood cell membranes to promote blood clotting [59]. The hydrophobically modified surface hinders the process of local fluid exchange between wounds and the external environment. This helps prevent bacterial and other contamination of the wounds. Chitosan-based hemostatic materials have been extensively studied in rat wound models, rat femoral artery trauma models, and rat liver injury models.

Various components and forms of hemostatic materials used to realize hemostasis.

| Material | Form | Testing model | Efficacy | Ref. |

|---|---|---|---|---|

| Chitosan | Chitosan/PVA/ZnO nanofiber mat | Diabetic rabbit subcutaneous wound model | Excellent antibacterial properties observed; promotes the production of granulation tissues and wound healing at the injured tissue. | [18] |

| Chitosan/silk fibroin/ Mg (OH)2 nanoparticles hydrogel | In vitro | The composite material exhibits favorable biocompatibility and can effectively inhibit the growth of Pseudomonas aeruginosa. | [19] | |

| O-nitrobenzyl alcohol/ carboxymethyl chitosan hydrogel | Rat liver injury model | Exhibits great adhesion and sealing properties; hemostasis is achieved within a short time period; decreases bleeding volume. | [20] | |

| Chitosan/Diatom-Biosilica Aerogel | Rat hemorrhage model. | Exhibits excellent water absorption properties; promotes the aggregation of red blood cells and adhesion and activation of platelets; accelerates hemostasis. | [21] | |

| Alkylated chitosan/ diatom-silica sponge | Rat tail transect model | Exhibits excellent biocompatibility; induces the activation, deformation, and aggregation of red blood cells and platelets, thus activating the intrinsic coagulation pathway and rapidly stopping bleeding. | [14] | |

| Quaternized chitosan/CNT cryogel | Mouse-liver injury model and mouse-tail amputation model | Demonstrates strong mechanical strength, superior blood absorption rate, and remarkably high blood cell and platelet adhesion and activation capacity. | [22] | |

| Cellulose/chitosan sponge | Mouse tail amputation model | Exhibits excellent absorbent and rapid shape recovery properties; exhibits effective antibacterial properties; cellulose/chitosan sponges have been studied in vitro and in vivo to achieve rapid hemostasis. | [23] | |

| HA | GelMA/HA-NB hydrogel | Porcine carotid artery hemorrhage and heart injury model | Gels quickly and adheres tightly to seal bleeding arteries and heart walls; withstands blood pressure of up to 290 mmHg, making it a superior wound sealant. | [24] |

| Gelatin | Gelatin nanofiber sponge | Rabbit ear artery injury model and liver trauma model | The composite sponge is characterized by low density, high surface area, and excellent fluid absorption capacity; aggregates and activates platelets in large quantities; accelerates the formation of platelet emboli; activates the extrinsic and intrinsic coagulation pathways. | [25] |

| Gelatin sponge with thrombin | Pig liver bleeding model | Easy to apply and can stop bleeding quickly to reduce the amount of blood loss realized. | [15] | |

| Peptide | Self-assembling peptide RADA16 nanofiber | Mouse diabetic wound model | Accelerates wound closure, collagen deposition, and tissue remodeling in healthy and diabetic mice. | [26] |

| Polylysine/thiolated chitosan hydrogel | Rat liver injury model | Gels quickly and exhibits excellent tissue adhesion properties. | [27] | |

| PEG | Tetra-PEG hydrogel | Rabbit liver hemorrhage model | Exhibits rapid gelation properties, strong tissue adhesion ability, high mechanical strength, rapid degradation properties, and controlled dissolution properties. | [28] |

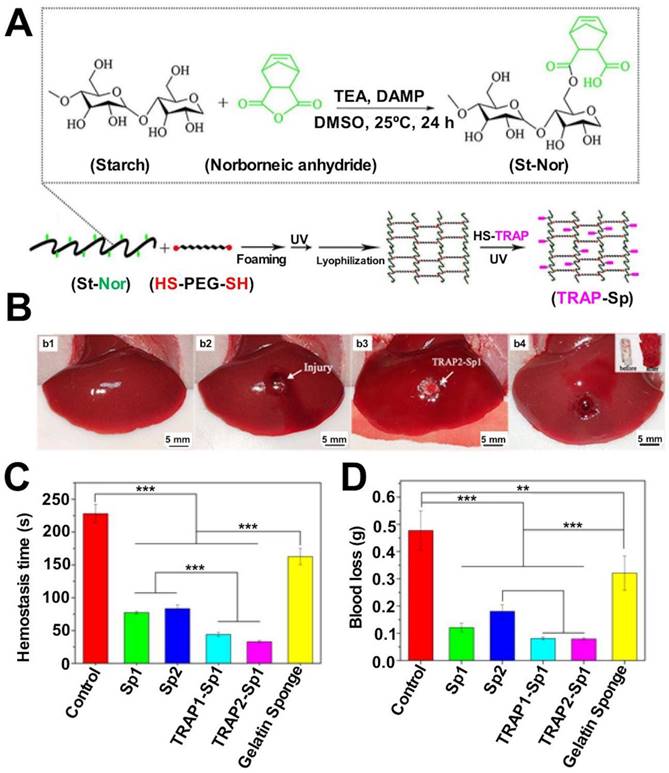

| TRAP-loaded starch/PEG sponge | Rat femoral artery and liver hemorrhage models | The superior water absorption property of the sponge helps absorb plasma, concentrate blood cells, and enhance blood clotting. Post water absorption, the shape-fixed sponge exhibits sufficient mechanical strength to apply pressure to the wounds to promote hemostasis. | [29] | |

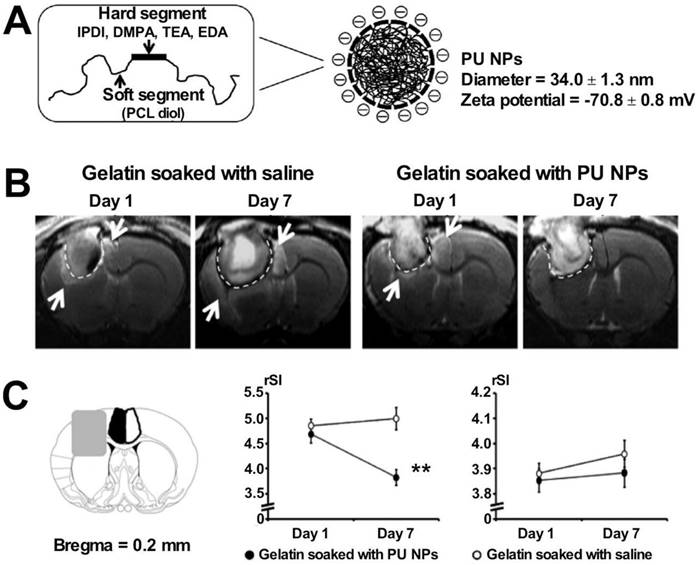

| PU | PU nanoparticle | Rat neurosurgical model | Hemostatic agents containing PU NPs exhibit anti-inflammatory and neuroprotective property in vivo; promotes procedures involving fragile tissues or organs. | [30] |

| PU based adhesive | Porcine vascular suture model | Applied to porcine vascular sutures to effectively prevent perioperative suture line bleeding; does not produce an inflammatory response that affects healing. | [31] | |

| PVA | PVA/oxidized betaine polysaccharide Schiff base aerogel | Whole skin defect model | Exhibits promising antimicrobial and hemostatic properties that help reduce inflammation; promotes angiogenesis; accelerates epithelialization to accelerate wound healing. | [32] |

| PVF sponge with pore-filled chitosan hydrogel, CaCO3 particle, and silica particle | Wistar rat liver hemorrhage model | The application of PVF-based composites significantly reduced the bleeding time (78.3-90.4%) compared to the commercial hemostatic product Celox™. | [33] | |

| PCL | PCL/gelatin nanofibers loaded with 1% lawsone | Rat wound model | PCL/Gel nanofibers loaded with 1% lawsone significantly improves the cell attachment and proliferation properties; promotes wound healing. | [34] |

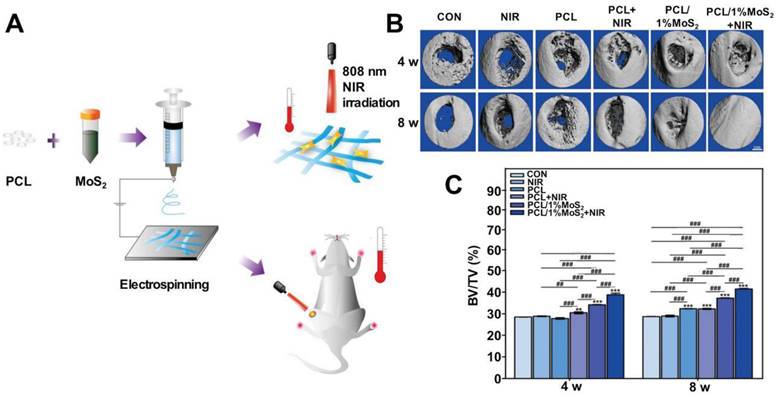

| CNT-coated PCL nanofiber | Rat calvarium bone defect animal model | Inhibits inflammatory response; promotes angiogenesis; drives MSC adhesion; promotes bone regeneration. | [35] | |

| PLGA | PLGA/PEG/ SiO2 nanofiber | Porcine liver laceration model | The composite nanofibers can be deposited directly onto the surgical site in the form of a solid fiber pad for ease of application. It exhibits excellent biocompatibility and sealing properties. | [36] |

| PEO | PEO/chitosan nanofiber mat | Porcine liver laceration model | Model experimental studies have confirmed the superior biocompatibility and hemostatic properties of PEO/chitosan nanofiber mats, which can be used to repair liver damage and achieve a high biodegradation rate. | [37] |

| Silica | Silica/chitosan sponges | Mouse tail amputation model | The silica/chitosan sponges are characterized by promising water absorption properties and mechanical strength; these help achieve excellent hemostasis in the mouse tail amputation model. | [14] |

| Silica nanoparticles for loading tannic acid | Mouse tail amputation model | Superior antibacterial properties and hemostatic properties. | [38] | |

| Chitosan/hydrocaffeic acid/SNP | Rat femoral artery trauma model | It can form a network structure with fibrin in the blood to improve the mechanical strength of blood clots and promote hemostasis and wound healing ability. | [39] | |

| Graphene | GO/gelatin aerogel | In vitro | Exhibits good water absorption properties; negative charge on its surface can promote hemostasis; red blood cells adhere to its surface, facilitating the formation of a stable fibrin network that promotes hemostasis. | [40] |

| Graphene/MMT composite sponge | Rabbit artery injury model | The composite sponge exhibits good water absorption capacity and can be used to rapidly stop bleeding in a rabbit arterial injury model without remaining in the blood vessels and causing thrombosis. | [41] | |

| CNF/copper-containing glass aerogel | In vitro | CNF/copper-containing glass aerogel can promote angiogenesis effectively; exerts excellent bactericidal effects, which promote hemostasis and wound healing. | [42] | |

| Platelet-derived nanovesicle | Natural platelet-derived nanoparticles prepared by hypotonic ultrasonication | Mouse tail transection bleeding model | The natural, biocompatible platelet-derived nanoparticles can be used to achieve hemostasis when injected; inflammatory reactions are not caused. | [43] |

| Platelet mimic | Liposomes with surface-decorated collagen and vWF-binding peptide | Mouse tail transection bleeding model | The surface of the liposomes is modified using a variety of mimetic peptides, which can effectively mimic the processes of platelet adhesion and aggregation to form platelet thrombi and achieve hemostasis. | [44] |

(PVA: polyvinyl alcohol; CNT: carbon nanotube; HA: hyaluronic acid; GelMA: gelatin methacrylate; PEG: polyethylene glycol; TRAP: thrombin receptor agonist peptides; PU: polyurethane; PVA: polyvinyl alcohol; PVF: poly(vinyl formal); PCL: polycaprolactone; PLGA: poly(lactic-co-glycolic acid); PEO: poly (ethylene oxide); SNP: silicon dioxide-based nanoparticle; GO: graphene oxide; CNF: carbon nanofiber)

Commercially available chitosan-based hemostatic materials (e.g., Hemcon®, Chitoflex®, and CELOX®) have exhibited excellent efficacy in trauma and surgical hemostatic applications. Chitosan-based hemostatic materials exhibit limited hemostatic effects and cannot be used to effectively control extensive bleeding [60]. These limit the application prospects of these materials.

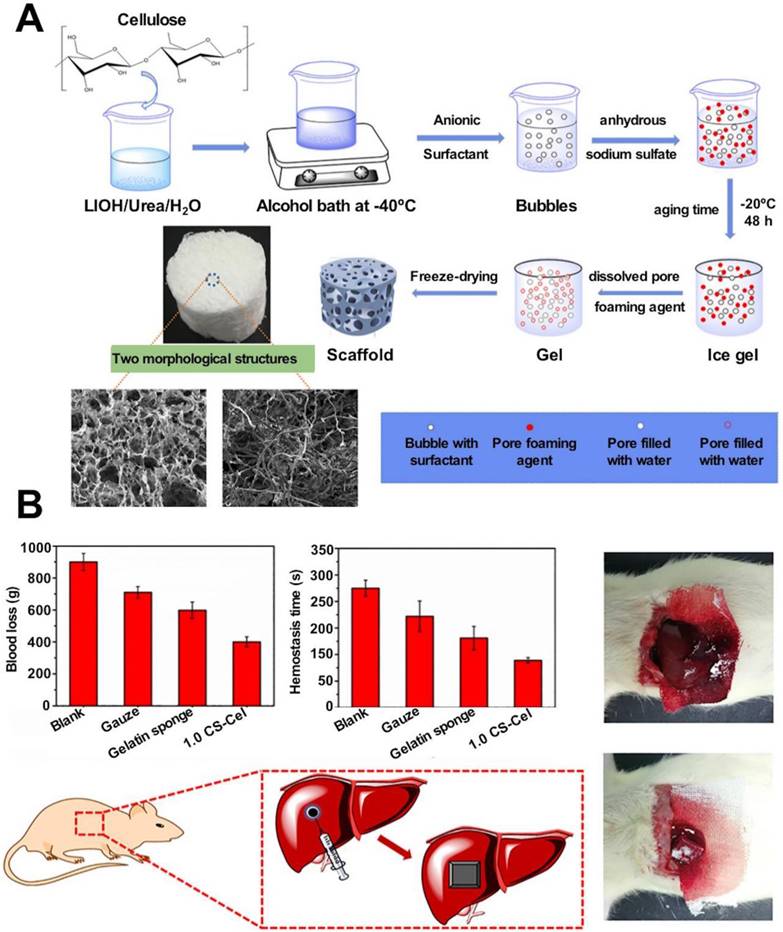

Cellulose is a macromolecular polysaccharide that is present in abundance in plants and bacteria. It is used for hemostasis and can be used to absorb water quickly. Cellulose fills the site of bleeding, providing physical compression to stop bleeding [61]. Cellulose contains acidic carboxyl functional groups, which can bind with Fe3+ ions in hemoglobin. This results in the formation of brown gels that help close capillary ends and stop bleeding [62]. It can potentially activate platelets to accelerate hemostasis [63]. Oxidized cellulose (OC) is a cellulose derivative that is synthesized following the oxidation of TEMPO (2,2,6,6-tetramethyl-1-piperidinyloxy). The method helps increase the anionic carboxyl group content on the cellulose surface. A large number of hydroxyl groups are oxidized to carboxyl groups to reduce surface water repellency [64, 65]. OC introduces a large number of carboxyl groups on the surface, lowering the local pH and causing non-specific platelet aggregation. This can potentially result in thrombosis and the promotion of hemostasis. The process can help in wound healing. The relatively low pH of OC helps inhibit the growth of a wide range of gram-positive and gram-negative microorganisms [66]. Cellulose is commonly prepared as hemostatic material together with other active coagulation ingredients. For example, OC-based nanofibers loaded with thrombin exhibit excellent biocompatibility and rapid water absorption properties. These can be used to study models of rat liver injury to significantly shorten clotting time and reduce bleeding volume [67]. The OC-based commercial hemostatic material Surgicel® is particularly effective in stopping bleeding during surgery. It can also be used to stop small arterial bleeding. The material is used during neurosurgery to reduce intracranial hematomas in bleeding patients [33]. However, the acidic environment can potentially generate an inflammatory response in tissues, prolonging the wound-healing process. This may also damage peripheral nerves. The slow degradation of cellulose-based hemostatic materials significantly hinders the application prospects of the materials. These may cause foreign body reactions and adhere to the wound area, interfering with epithelial growth and resulting in delayed healing [68, 69].

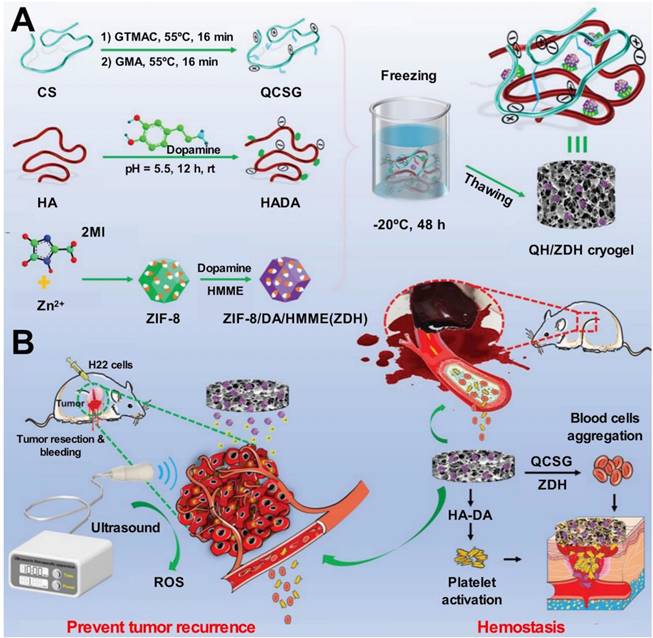

HA, an acidic mucopolysaccharide, is a natural component of the body with excellent biocompatibility [70]. HA contains a large number of hydroxyl groups and can form hydrogen bonds with water molecules to absorb water and increase the concentration of platelets and clotting factors [71]. It is also involved with the process of releasing inflammatory cytokines (such as TNF-α, IL-1β, and IL-8) [72]. It directs the processes of fibroblast invasion and proliferation to promote wound healing [71, 73]. It should be noted that HA is easily soluble in water and has a short residence time in tissues. The mechanical properties of HA were improved, and its degradation rate was controlled following the processes of cross-linking [74, 75], esterification [76, 77], molecular modifications [78, 79], and compounding [80, 81]. The addition of a certain amount of hydrazinolyzed 3,3'-dithiopropionic acid (DTP) to an aqueous solution of HA to obtain a mercapto-hyaluronic acid derivative (HA-DTPH) resulted in a decrease in the rate of degradation of HA and an improvement in the wet tissue [82, 83]. Some researchers used tyramine to modify HA by introducing phenol groups to the backbone of HA. This resulted in the production of hydrogels with controlled mechanical strength [84]. Hydrogels based on HA-tyrosine (HA-Tyr) prepared following the process of enzymatic cross-linking could improve the extent of hemostasis achieved and effectively increase the cell adhesion property of the material [74, 85-87]. Bagheri et al. studied the efficacy of phenolic hydroxy HA (HA-Ph)-based hydrogels (characterized by different degrees of cross-linking) on the cell adhesion and proliferation properties of the materials [75]. The drawbacks of using modified HA as a hemostatic material lie in the difficulty of removing the material when necessary. HA-based hemostatic materials have been examined in the mouse model of total skin injury, the arterial hemorrhage model, the liver injury model, and the porcine left ventricular penetration model [24].

Alginate, similar to HA, is highly absorbent and can increase the concentration of platelets and coagulation factors. Alginate can increase the local Ca2+ concentration and accelerate the coagulation process [88, 89]. Furthermore, alginate exhibits cellular chemotactic activity, which promotes wound repair. Alginate oligomers (AOS), which retain the physical and chemical properties of the parent polymer and can be modified, are the focus of current research [90, 91]. The hydroxyl group in the glyoxylate units can be transformed into an aldehyde group in the presence of strong oxidizing agents. This transformation helps to improve the degradation properties of the material. AOS can cross-link with various metal ions, such as Ca2+, to form gels that improve hemostasis and viscosity [92-95]. Alginate is not designed to treat dry wounds with hard crusts. Numerous studies have been conducted on the diabetic foot ulcer model, and the alginate-based commercial product Algosteril® has been approved clinically for wound care dressing.

Collagen, a porous material, expands following blood absorption. It forms a mesh for blood clotting and sealing cracks in blood vessels or wounds. It can activate platelets and induce the release of physiological aggregating agents such as ADP and TXA2, resulting in the irreversible aggregation of platelets. It also functions as a platelet adhesion matrix that helps form blood clots for hemostasis [96-98]. Collagen promotes the process of proliferation during the wound repair process [99]. Collagen tends to cause allergic reactions, exhibits poor adhesion properties, and cannot be easily degraded, and these properties hinder the practical applications of the material. Partial hydrolysis of collagen results in the production of gelatin, and it can be used to address (to a certain extent) the safety issues posed by collagen [100]. Gelatin has been processed in various forms for clinical applications, and the most commonly used gelatin-based material for hemostasis is the gelatin sponge [101, 102]. Slezak et al. compared the hemostatic effects exerted by the collagen and thrombin-containing powder agent Hemoblast® and the flowable gelatin-thrombin matrix Floseal® in a porcine liver hemorrhage model. The results revealed that the gelatin-the thrombin-based system was more efficient than the other model in reducing bleeding. The ease of applicability of the former was better than that of the latter [15]. Wang et al. used gold/silver clusters to functionalize gelatin sponges that exhibited good antibacterial properties [103]. Additionally, gelatin and collagen are popular materials for wound healing because they are biocompatible and biodegradable. Commercial gelatin-based hemostatic products, such as Floseal® and Endo Avitene®, exhibit excellent hemostatic efficacy in clinical settings. FloSeal® is a commercial hemostatic material consisting of animal collagen, glutaraldehyde, and human coagulation enzymes in fibrin glue. It is currently used to treat obstetric bleeding [104], nasal bleeding [105, 106], and joint bleeding [107]. Moreover, it is also used for intracranial tumor removal [108]. Collagen and gelatin are prone to allergic reactions and are liable to degradation.

Fibrin significantly affects the coagulation process and can form insoluble fibrin multimers under the effect of thrombin and Ca2+. Multimers trap platelets and blood cells to form blood clots [109, 110]. It can also stimulate the growth of capillary endothelial cells and fibroblasts, and the process promotes wound healing [111]. Tissuccol®, a commercial fibrin glue, produced satisfactory hemostatic results when used to treat upper gastrointestinal bleeding and splenic rupture. It could also be used to treat hepatectomy [81] efficiently. Fibrin-based materials cannot be used to stop bleeding from large arteries and veins, and this can be attributed to the long clotting time. The use of fibrin-based materials may result in animal or human blood-borne infections [112].

Natural polymers can facilitate platelet aggregation and activation through various mechanisms to achieve rapid hemostasis and promote wound healing. The aldehyde group in oxidized dextran can serve as a cross-linking agent for the preparation of hydrogels and sponges, and it can also cross-link with amino groups on the tissue surface to promote the local adhesion of hemostatic materials [113]. The high price, poor mechanical properties, and tendency of natural polymers to cause allergic reactions limit the development of natural polymer-based hemostatic materials.

Synthetic polymers

It is easier to functionalize synthetic polymers synthesized following physical or chemical methods than natural polymers. Hence, these materials have attracted immense attention in the field of research of hemostatic material research.

Solutions made of self-assembling peptides can gelate rapidly with blood, and the formed hydrogel can seal wounds. Thus, such hydrogels can be used as hemostatic agents. The molecules in the peptide solution can trigger the processes of self-assembly and gelation when they encounter charged amino acid molecules in the blood. When applied to a wound as hemostatic material, the peptide can rapidly absorb the surrounding fluid, increase the local concentration of platelets and clotting factors in the wound, initiate the peptide self-assembly process, and form a nanofibrous scaffold to promote the exudation of red blood cells and blood from wounds [114]. Polylysine contains abundant primary amine groups that are cationic in neutral aqueous solutions. The ionic attraction between these amino groups and the residues exposed under conditions of tissue damage demonstrate the potential tissue adhesion property of polylysine [115]. Nie et al. cross-linked thiolated chitosan and ε-polylysine through maleimide groups to form (in situ) a fast-curing hydrogel that could effectively adhere to rat liver wounds and help achieve rapid hemostasis [27]. Zhang et al. realized the in situ preparation of hydrogels characterized by high mechanical strength and short gelling time by cross-linking polyacrylamide units containing a large number of amide groups with ε-polylysine. The prepared systems were used to study a model of rat liver injury, and excellent tissue adhesion and hemostatic properties were observed. It was observed that the extent of bleeding from the synthetic hydrogel-treated wounds was 1/7th of the extent of bleeding observed for the untreated groups [116]. Peptide sequences other than polylysine also perform well in the field of hemostatic materials. Charbonneau et al. prepared a peptide sequence consisting of lysine and leucine residues bound to the surface of a biocompatible polymeric hydrogel matrix to form a hemostatic material. This material was used to test a rabbit ear bleeding model, and it was observed that the bleeding time could be reduced by 40% using this material. When a rabbit liver injury model was tested using the prepared peptide sequence, the extent of surface damage realized was less than the extent of surface damage realized using the commercial zeolite powder agent QuikClot® [117]. RADA-16 (RADARADARADARADA) is a short peptide sequence consisting of arginine, aspartic acid, and alanine. This system exhibits self-assembling properties and can spontaneously assemble to form b-folded and nanofiber lattice structures under certain conditions. The composition of the structure is stable. The structure is adjustable and is characterized by high biocompatibility and non-immunogenicity. These materials mimic the porosity and structure of the extracellular matrix in vivo, can provide a suitable microenvironment for cell growth, promote the repair and reconstruction of damaged tissues, and promote the drug delivery process [118]. Wang et al. used a RADA-16 self-assembled peptide system to rat spinal cord transection and liver injury models. They demonstrated that the peptide significantly reduced bleeding time and reduced bleeding volume [119]. Yang et al. prepared a copper peptide-functionalized RADA16 system that was used to study a diabetic mouse model to effectively accelerate the processes of wound closure and tissue repair [26]. Self-assembled peptide sequences can be potentially used to realize hemostasis, although some persistent disadvantages hinder their clinical applications. The peptides are not readily accessible, and some peptides need to be preheated and sonicated prior to use. The cost-inefficiency of the preparation process hinders the practical applications of the material.

PEG is widely applied in the medical field as they are characterized by excellent properties. Amphiphilic copolymers containing PEG are adsorbed on the surface of medical polymer materials to improve the biocompatibility of medical polymer materials in contact with blood [120, 121]. PEG adheres well to tissues and is commonly used as a drug carrier that promotes slow drug release [122, 123]. It is also used as a carrier of immobilized enzymes [124]. Furthermore, PEG can crosslink with tissues and form physical barriers to inhibit bleeding. PEG-based hydrogels exhibit good water absorption properties, and these can increase the concentration of platelets and coagulation factors around wounds. These materials are suitable for the hemostatic closure of traumatic organ injuries [125]. A high relative molecular weight characterizes Dobby PEG derivatives, and these can form hydrogels characterized by excellent water barrier and tissue activity. It can gradually be degraded in the body and completely excreted under conditions of in vivo hemostasis. The material degrades slowly and may cause foreign body reactions, delaying the process of wound healing. Wu et al. introduced cyclized succinate groups into the hydrogel matrix to enable the rapid degradation of the sealant to promote the degradation of PEG and reduce possible damage to tissues [28]. PEG reacts with other polymers to form highly functional copolymers. PEG and acrylic acid can be formed following esterification reactions, and rapid gelation to form the hydrogel from the resulting poly (ethylene glycol) diacrylate (PEGDA) could be triggered using a photoinitiator in the presence of ultraviolet (UV) light at room temperature [126]. This property makes the materials suitable for rapid wound closure [127]. The property of tissue adhesion significantly affects the applicability of hemostatic materials. This property can be improved by functionalizing PEG with aldehyde groups or dopamine. Hydrogen or Schiff base bonds are formed, and amino groups are exposed in the tissue. Each coin has two sides, and the preparation of functionalized hemostatic materials poses difficulties.

PU, a synthetic polymer, exhibits good biocompatibility and degradability. It is easy to process and is used in a wide range of fields, such as trauma dressing and tissue engineering. PU foams can induce the processes of coagulation cascades and platelet aggregation [128]. PU-based sponges can preserve wound moisture, promoting the process of repair of tissues based on the theory of “moist healing”. The mesh-like structure helps control the rate of water vapor transmission and resists bacterial invasion. The self-expanding PU foam provides rapid response and is characterized by rapid volume expansion. Close-fitting of the trauma surface can be realized using the material, and this can be used to study animal models of hypothermia in traumatic hemorrhagic shock (such as the porcine lethal liver hemorrhage model). It has been found that the materials can be used to rapidly and effectively reduce the amount of bleeding in cases of lethal trauma, significantly improve vital signs, ensure the perfusion of vital organs, and generate conditions for subsequent definitive hemostatic treatment [129]. The commercial formulation NasoPore® (a PU-based foam) demonstrated improved hemostasis and provided good patient satisfaction in a clinical trial, as reported by Pawel et al. The researchers used the model for nasal caulking following endoscopic sinus surgery [13]. The excellent tissue adhesion properties of PU make it suitable for application as a sealant in vascular procedures. Lisanne et al. used a PU-based adhesive to study a porcine model of vascular injury repair. The results revealed that the material could effectively improve the outcome of cardiovascular surgery, reduce the incidence of vascular anastomotic fistulae, and efficiently fix sutured vascular anastomoses rapidly and safely without interfering with the process of vascular wound healing [31]. Huang et al. exploited the anti-inflammatory properties of PU nanoparticles (NPs) by combining them with gelatin. The material was implanted in the cortex of injured rats in a rat neurosurgical model, and anti-inflammatory PU NPs were released. The process significantly shortened the hemostasis time and reduced the extent of brain edema. The degree of the inflammatory response generated in the brain was also reduced, facilitating the process of tissue repair [30]. PU materials degrade relatively slowly in vivo compared to other materials. The prolonged in vivo polymerization time of Tissue Glue®, a commercial PU-based formulation, hinders its application prospects.

The PVA-based hemostatic sponges, prepared following a series of processes such as cross-linking, foaming, curing, and sterilization, are characterized by non-fibrous porous structures [130]. These perform well and exhibit excellent hydrophilic and liquid-absorbing properties. These also exhibit good biocompatibility and stable chemical properties. PVA swells following water absorption and can be used to realize localized compression and physical hemostasis. Therefore, these materials are commonly used for compression hemostasis of narrow cavities in humans (such as nasal [131, 132] and anal cavities). Kim et al. used PVA-based nanocellulose sponges to study a rabbit nasal mucosal defect model, and experiments demonstrated that PVA sponges significantly promoted the mucosal regeneration during the early stages of mucosal wound healing of mucosal wounds in noses [132]. PVA does not contain pro-coagulants and relies primarily on the water-absorbing and swelling properties of the sponge material to stop bleeding. Thus, the material is characterized by a narrow application range and cannot be used to treat patients suffering from coagulation disorders.

PCL has been approved by the U.S. Food and Drug Administration (FDA) for a wide range of biomedical applications as it exhibits excellent biocompatibility and good biodegradability. PCL is widely used for producing and processing drug carriers, nanofiber spinning agents, and implantable plastic materials, as it is characterized by excellent shape memory and temperature control properties. PCL, used to develop hemostatic materials, can form compounds with chitosan [100, 133, 134], gelatin [100, 135], collagen fibers [136], and starch [100] to improve the biocompatibility and degradability of the materials without changing or improving the hemostatic properties. Cheng et al. used the process of phage incorporation to develop PCL/collagen fibers following the electrostatic spinning technique. They studied rabbit back injury and deep muscle injury models, and the results indicated that the compounds exhibited excellent antimicrobial effects and could be used to achieve rapid hemostasis [136]. The PCL material used for the preparation of nanofibers could efficiently cover the maximum contact surface area of wounds. Hu et al. fabricated alginate/PCL composite fibers that could be used to dress a mouse back wound model. The material could effectively promote the processes of wound healing and tissue repair. Alginate could provide a moist environment for the wound and promote PCL adhesion [137]. The hydrophobic nature of PCL does not promote adhesion. Hence, surface modification with hydrophilic or mucoadhesive materials is required to prepare hemostatic materials. The degradation rate of PCL is slow, and its degradation rate and drug release profile must be considered when it is used as a carrier of hemostatic drugs.

Acrylate polymers exhibit excellent biocompatibility, broad adhesive properties, water resistance, and durability, which dictate the development and application prospects of the materials in the field of medical adhesives [138]. Moreover, these materials are easy to formulate. Medical bioadhesives can adhere tightly to tissue surfaces and close wounds. There are two major acrylate-based tissue adhesives: polyacrylate adhesives and α-cyanoacrylate adhesives. Polyacrylate adhesives are extensively used as tissue adhesives and implant-filling materials. These are widely used as filling materials for orthodontics. These also find their applications in the fields of dental repair, artificial joint replacement, and bone defect filling [139]. Polymethylmethacrylate (PMMA)-based bone cement is used to treat unstable fractures and in the field of artificial joint replacements. This material significantly improves the firmness of a prosthesis and reduces the degree of long-term loosening of the prosthesis [140]. However, PMMA-based bone cement does not exert osteogenic effects to promote bone healing and does not match the mechanical properties of natural bone. These properties hinder their applications in clinical settings. Li et al. prepared PMMA-based bone cement-containing active nano-MgO particles (nano-MgO/PMMA), which significantly improved the biocompatibility of the material and significantly increased the expression of osteogenic genes. The use of the material also promoted the production of calcium nodules in bone tissues when applied to a model of critical cranial bone defect model [141]. Since 1950, α-cyanoacrylate-based adhesives have been introduced into the medical field, and these are the first and most widely available tissue adhesives. These adhesives can be used to realize rapid and intense bonding. They exhibit excellent biocompatibility and relatively low toxicity. The degree of tissue rejection is also low [142]. The α-cyanoacrylate unit contains negatively charged nitrile and ester groups. This makes the double bond in the monomer extremely reactive, and the process of anionic polymerization can be rapidly realized under these conditions under the influence of weak bases. Instantaneous bonding is realized under these conditions while encountering bleeding wounds. Several tissue adhesives, primarily α-cyanoacrylates, are widely used in a variety of surgical procedures. Alfredo Moreno-Egea conducted a randomized controlled trial to explore the effectiveness of n-hexyl-α-cyanoacrylate as a suture substitute in inguinal hernia surgery. The study included 208 patients, 102 of whom were treated with tissue adhesives. The results demonstrated that the use of n-hexyl-α-cyanoacrylate significantly reduced the mean operative time and decreased postoperative pain [143]. Cyanoacrylate was effectively used during the endoscopic ultrasound-guided treatment of fundic varices formed under conditions of portal hypertension [144]. The α-cyanoacrylate-based adhesive, applied to a dog model with severe liver injury, can close wounds and reduce bleeding [145]. Some problems still need to be addressed to increase the application prospects of α-cyanoacrylate-based adhesives. These adhesives may cause foreign body reactions in living tissues and hinder the process of tissue healing. The poor elasticity of the adhesion site and the poor flexibility with the surface tension of the organ limit the practical applications of the adhesive.

PEO is a water-soluble polymer that exhibits excellent biocompatibility, non-immunogenicity, and non-toxicity. It resists the non-specific adsorption of proteins and is frequently used to develop various drug carriers and anti-adsorption coatings [146]. In the field of hemostatic material development, PEO is primarily used as an additive to improve the performance of other active ingredients. Chitosan, as a positively charged hemostatic active substance, can promote wound hemostasis by aggregating red blood cells, activating platelets, and activating coagulation cascade reactions [53]. The chitosan-based nanofibers fabricated following the electrostatic spinning method adhere tightly to tissues and exhibit excellent biocompatibility and degradability. The application of PEO to the chitosan electrospinning process can effectively reduce the surface tension and viscosity of the chitosan solution, promoting the formation of nanofibers [147]. Deineka et al. used nanofiber mats formed using PEO and chitosan to study a rat liver injury model, and the composite nanofibers significantly reduced the bleeding time. The material exhibited improved degradability and tissue repair compared to the conventional chitosan sponge [37]. The composite nanofibers formed from PEO and chitosan exhibited reduced adhesion on the EpiSkin model. This helped to safely remove the hemostatic material from the wound surface without causing secondary bleeding [148]. Poly (propylene oxide) (PPO) is insoluble in water, biocompatible, and stable. It is usually combined with PEO to prepare high-performance materials. Pluronics® is a PEO-PPO-PEO copolymer that the FDA has approved for usage as an injectable pharmaceutical excipient [149]. PEO and PPO do not promote tissue hemostasis or blood coagulation by themselves, and these are mostly explored together with other hemostatic active ingredients for the development of hemostatic materials.

Most synthetic polymers lack the biological activity required to promote blood clotting. These function as substrates or cross-linking agents for hemostatic materials. It is difficult for simple polymers to meet the special performance requirements of biomedical materials. Researchers are widely compounding synthetic polymers with different biologically active natural polymers to integrate their strengths and obtain composite materials that can be effectively used in clinical settings. PU sponge is a porous foam obtained by foaming PU. The interior of the material appears porous, and the material exhibits excellent physical and mechanical properties. Aqueous PU and sulfated chitosan are blended using glutaraldehyde as the cross-linking agent to form a cross-linked semi-interpenetrating network characterized by excellent hemocompatibility [150].

Inorganic materials

Inorganic materials can be used effectively for hemostasis. Zeolite has long been noted for its hemostatic properties, and in 2002, QuikClot®, the first generation of zeolite hemostatic products, was introduced as first aid equipment for the U.S. military [151, 152]. Zeolite is a porous crystalline aluminosilicate, and its porous structure allows for positive water absorption. This helps increase the concentration of local platelets and clotting factors. The negative surface charge can activate positively charged Factor XII, triggering a cascade reaction of endogenous clotting [153, 154]. Zeolites not only tend to enter capillaries (resulting in thrombosis) but also tend to absorb water and release excessive heat. This can potentially damage the skin [155]. Fan et al. prepared calcium-based zeolites that effectively shorten clotting time and help avoid adverse effects. The FDA has approved the patented zeolite hemostatic gauze for use in clinical settings [156].

Mesoporous silica is characterized by a high density of silanol anions on its surface. These anions can interact with the positively charged amino acids on the surface of the coagulation factor XII to accelerate the coagulation cascade reaction and promote hemostasis. Mesoporous silica exhibits good biocompatibility and exerts low degrees of side effects when used in the human body [21]. Characterized by the presence of large pores, it can attach to thrombin [157], antimicrobial agents [158, 159], and analgesic drugs [160] to achieve effective wound treatment. Wang et al. used silica nanoparticles for loading tannic acid. These materials could effectively promote the activation of the coagulation cascade reaction and reduce the hemostasis time by 65%. These also exhibited excellent antibacterial properties [38]. Silica- and chitosan-based composite sponges were used to study a rat tail break model, and these materials exhibited excellent hemostatic properties [14]. The positive charge on the chitosan surface and the negative charge of the diatom attracts each other, reducing the amount of powder residue on the trauma surface.

Graphene is readily functionalized and widely used in various biomedical fields, such as drug delivery [161, 162], bioimaging [163, 164], and tumor therapy [162, 165]. Graphene oxide (GO) has a 2D sheet structure and contains numerous oxygen-containing functional groups on its surface. These groups can activate platelets to trigger aggregation, and the material exhibits excellent biocompatibility and hydrophilicity. Thus, GO can potentially be used for trauma treatment [40, 166]. Graphene-based sponges are characterized by good water absorption abilities, and these are functionalized on the surface. Thus, multiple functional composites can be prepared from GO, laying the foundation for their development as hemostatic materials. Li et al. prepared graphene/montmorillonite composite sponges (GMCS) using graphene-immobilized montmorillonite (MMT) particles. GMCS-activated Factor XII with a negative charge cascade on the surface of MMT could be used to accelerate hemostasis, and the entry of MMT particles into blood vessels could be prevented [41].

Metal-containing materials

Metal ions such as Ag, Zn, and Cu exhibit broad-spectrum antimicrobial properties, superior heat resistance, good dispersibility, and low drug resistance. These materials are widely used to develop various biological materials and medical devices. Various materials containing metal ions have been effectively used in the field of hemostasis. Ca2+ significantly affects the physiological coagulation pathway and can activate Factor X. It participates in the formation of prothrombin complexes and activates Factor XIII to form insoluble fibrin multimers that exert hemostatic effects [167-169]. The precipitation of calcium ions on the surface of chitosan nanofibers can effectively accelerate the platelet activation process and shorten the hemostasis time. The composite material prepared by combining hydroxyapatite with bacterial cellulose promotes cell proliferation [170]. The calcium-based zeolite can be used effectively to realize hemostasis [156].

Silver ions are antimicrobial agents, and their incorporation into mesoporous silica-chitosan composites can improve the antimicrobial properties of the composites without increasing cytotoxicity [171]. Microporous chitosan-polyethylene glycol hydrogels containing copper ions exhibit good stability. These compounds exhibit excellent antimicrobial activity and generate an excellent keratin-forming cell response [172]. Zinc is considered a platelet modulator that can promote the process of platelet activation [173]. Cellulose oxide nanoparticles loaded with Zn ions can significantly improve the mechanical and antimicrobial properties of bionic calcium alginate hydrogels [174]. Carboxymethyl chitosan zinc (CMCS-Zn) is a degradable biomaterial that can be used to treat bone defects effectively, and this composite inhibits the occurrence of bone infections [175]. Cerium oxide exerts a significant neuroprotective effect under conditions of oxidative stress [176]. Liu J et al. synthesized cerium-containing spherical mesoporous bioglass particles, effectively reducing the clotting time and promoting cell proliferation. The results were arrived at by conducting in vitro tests [177]. Magnesium ions significantly affect the processes of cell adhesion, proliferation, and mineralization [178]. Bian et al. prepared bioactive hydrogels based on HA and bisphosphonate-magnesium nanoparticles, which could significantly upregulate the production of alkaline phosphatase (ALP) and effectively promote the repair of bone tissues [179]. Lu et al. loaded Fe3+ onto the surface of sodium alginate grafted dopamine-modified poly (lactic acid) (PLLA) complexes. The resulting material could effectively concentrate local blood components and shorten coagulation time. The material exhibited excellent antibacterial properties against E. coli and Staphylococcus aureus [180]. Zinc ions also exhibit significantly high antibacterial activity, and these are used to develop hemostatic materials [18].

Others

Platelet-derived nano-vesicles and synthetic platelet mimics can be used to develop hemostatic materials. Platelets are small pieces of cytoplasm that are shed from the cytoplasm of mature megakaryocytes. These participate in hemostasis and coagulation. The von-Willebrand Factor (vWF) receptors on the surface of collagen fibers are exposed when vascular endothelial cells are damaged. Glycoprotein Ib (GPIb) on the platelet surface recognizes the bound vWF receptors and rapidly adheres to the site of injury. Activated platelets release epinephrine, ADP, and thrombin, which promote the process of platelet aggregation, resulting in the formation of thrombi. Platelets present a phospholipid surface that adsorbs large amounts of coagulation factors, increasing the speed of the clotting response. Platelet-derived particles can promote the processes of megakaryocyte differentiation and platelet production. Jung et al. developed platelet-derived nanovesicles following a hypotonic ultrasound method. The nanovesicles can adhere and aggregate to stop bleeding in the presence of calcium ions and thrombin. Reduced pro-inflammatory cytokines, such as TNF-α, IL-6, and IL-1β, which can potentially hinder the processes of macrophage activation and phagocytosis, are produced under these conditions [43]. Platelet mimics can mimic and enhance the hemostatic capacity of platelets. The shelf life is increased, and the degree of contamination is low. These materials can be used to develop hemostatic materials in the future. Christa et al. used liposomes as model particles with collagen, vWF binding peptides, and fibrinogen mimetic peptide (FMP) decorated on the liposome surface. The functionally integrated platelet mimetic liposome structure exhibited significantly high hemostatic efficacy when used to study the mouse tail transection model [44]. James et al. developed Arg-Gly-Asp (RGD)-based functionalized nanoparticle platelet mimics. Poly (lactic-co-glycolic acid)-poly-L-lysine (PLGA-PLL) was used as the core, and RGD sequences were combined with nanospheres via PEG to form the synthetic systems. The material could be used to effectively reduce the bleeding time in a severely traumatized rat model [181]. Several biomaterials are also used to develop hemostatic materials. Extracts of lactic acid bacteria combined with nitric oxide donors can be used to form biomimetic phage microparticles exhibiting antimicrobial properties. These microparticles are further encapsulated using graphene oxide, and the resulting antimicrobial hydrogels are prepared to promote the process of wound healing [182]. Herbal components such as curcumin have also been investigated for the development of hemostatic materials, and the materials exhibit good antibacterial activity [183].

Forms of hemostatic materials

The effectiveness of hemostatic materials depends not only on the active chemical composition but also on the selection of the appropriate form of the material to be processed. Nanofibers, hydrogels, nanoparticles, and sponges are common forms of hemostatic materials. Different forms of hemostatic materials are used under different conditions, and the pros and cons of using these materials differ based on the type and form of the material used.

Nanofibers

Any fiber with a diameter of less than 1 μm is a nanofiber. These ultrafine fibers have a specific surface area that generates excellent adsorption properties and surface activity. The pore sizes of the lattices and films composed of these extremely fine interwoven nanofibers are significantly small. The materials are characterized by high porosity and good surface adsorption properties. The high porosity of the nanofiber surface helps achieves moderate levels of wound drying, which promotes wound healing. Nanofibers can be classified into two types based on the preparation methods (spinning and molecular technology) followed. In this section, we introduce the application of nanofibers, prepared following the two methods, in the field of hemostatic materials.

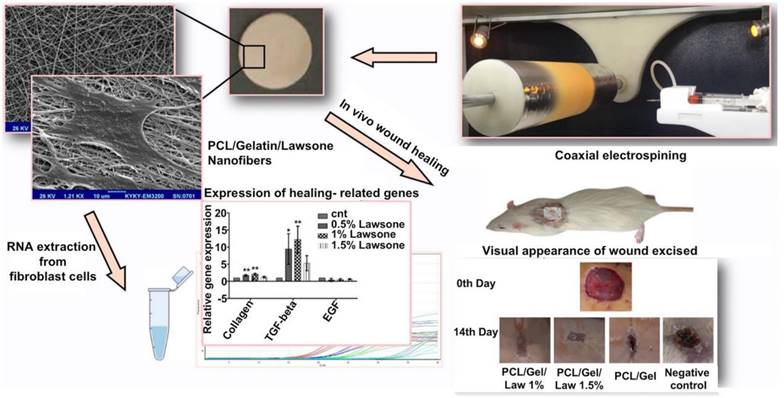

The electrostatic spinning technique was applied to prepare PCL-gelatin nanofibers loaded with different concentrations of Lawsone, and they were experimentally evaluated for wound healing effects in a rat wound model. Reproduced with permission from [34]. © 2018 Elsevier B.V. All rights reserved.

Spinning methods include electrostatic spinning [184], solution blowing, and centrifugal spinning [185] methods. The electrostatic spinning method is the most commonly used method for nanofiber preparation as the method is easy to execute. Moreover, the method is widely used in various fields and is characterized by high production efficiency. The electrostatic spinning technology involves the use of the electrostatic force generated under conditions of a high-voltage electric field to prepare the polymer solution extruded from a syringe at a certain flow rate [186]. The surface tension is overcome under these conditions, and a fine stream of charged polymer is ejected. The process is influenced by the electrostatic force, and the charged jet further accelerates to stretch and form a continuous ultra-fine fiber that is collected at the receiving end. Sardou et al. loaded the nanofibers prepared following the electrostatic spinning method with the PCL/gelatin mixture containing different concentrations of lawsone. The results of in vitro cell adhesion and proliferation experiments and those obtained by studying rat wound models revealed that PCL/gelatin nanofibers loaded with 1% lawsone can effectively promote the processes of fibroblast adhesion and proliferation. These can also promote wound healing and the formation of granulation tissues [34] (Figure 1). Ahmed et al. synthesized nanofiber mats by encapsulating ZnO particles with chitosan/PVA nanofibers prepared following the electrospinning process. Results of in vitro experiments revealed the significantly high inhibitory effects exerted by chitosan/PVA/ZnO nanofibers on a variety of bacteria, including Staphylococcus aureus, E. coli, and Pseudomonas aeruginosa. The chitosan/PVA/ZnO nanofibers exhibited strong antioxidant capacity in a diabetic rabbit wound model, inhibiting the development of local inflammation and promoting wound healing [18]. The polymer solution should be characterized by a certain level of conductivity for the efficient preparation of nanofibers following the electrostatic spinning method. This limits the choice of conductive polymers. Moreover, the electrostatic spinning method cannot be used for industrial production, as the products are obtained in low yields when this method is used. This resulted in the development of the solution spinning technology. Unlike the electrostatic spinning method, the solution-blowing spinning method involves the exploitation of the jet effect generated by high-pressure airflow when droplets overcome surface tension to form nanofibers [185]. The solution blow spinning technique is a highly efficient method that can be used to prepare materials within a short time. Electrostatic interactions and dielectric constants do not limit the process. Daristotle et al. prepared a mixture of solutions containing PLGA, PEG, and SiO2 nanoparticles with acetone as the solvent and deposited polymer nanofibers on a porcine liver wound model using a solution blow-spinning device. The results demonstrated the good hemostatic effect exerted by the nanofibers [36]. It should be noted that the fibers are formed randomly, and the expected morphology is not achieved when the solution spinning technology is used. Xie et al. manufactured nanofiber capsules following the processes of electrospinning, gas foaming, coating, and cross-linking. The capsules can be swallowed. Good scalability and absorption properties are achieved, and the materials are promising as alternative testing products to endoscopy that can be used to collect a large number of biological samples to help diagnose numerous diseases in a timely and accurate manner [187].

Molecular techniques are primarily used to prepare single- or multi-tube carbon nanotube (CNT) bundles. The three main methods used for the preparation of CNT bundles are arc discharge [188], laser ablation, and chemical vapor deposition [189]. Among these, the chemical vapor deposition method is the most popular as it is cost-efficient. This method can be used to produce materials with high yields, and the process can be executed under controlled experimental conditions. The chemical vapor deposition method is used to deposit catalysts on a flat substrate such as quartz. The method involves the passage of a carbon-containing gas at a high temperature to decompose, precipitate, and grow CNTs on the catalyst particles. This method can be used to produce ordered parallel/perpendicularly aligned CNTs that are characterized by high specific surface areas [189]. Patel et al. modified the surface of polymeric nanofibers with CNT and investigated the role of the composites in modulating inflammation, angiogenesis, and bone repair (in vivo). The CNT-coated nanofibers exhibited a reduced inflammatory response and enhanced angiogenic and angiogenic marker expression levels when injected subcutaneously into rats [35]. The electrical conductivity of CNTs can also induce osteoblast differentiation and cell proliferation through electrical stimulation, and these materials are frequently used to prepare synthetic bone matrices [190]. The major obstacle that hinders the further application of CNTs in biomedical fields is their toxicity toward tissue cells [191].

The nanofibers of natural or synthetic polymers prepared following the above methods can effectively adhere to and activate platelets to promote the processes of hemostasis and wound healing in cases of serious or irregular injuries. However, hemostatic materials are difficult to remove, and this problem is yet to be addressed.

Gels

Hydrogels

Hydrogel presents a three-dimensional network consisting of a macromolecular backbone and side chains containing hydrophilic or hydrophobic groups. It can absorb and retain large amounts of water by exploiting the cross-linked network. Its application in the field of hemostasis and wound healing can increase the concentration of local platelets and clotting factors and shorten the clotting time [192]. Most existing hemostatic materials adhere weakly to wet tissues and cannot be effectively used to treat heavy-bleeding wounds. Hydrogels can effectively adhere to tissues, keeping the wound site moist to stop bleeding and promote healing. The hydrophilic groups in the hydrogel can bind tightly to the local protein or peptide units in tissues. The hydrogel adheres firmly to damaged tissues under these conditions [193]. Hydrogels can be classified according to the preparation method, source of the raw material, size of the material, and shape of the material. Herein, we discuss hydrogel-based hemostatic materials that are categorized based on the preparation method.

Hydrogels can be classified into physical and chemical hydrogels based on the hydrogel synthesis method followed and the nature of network bonding. Physical hydrogels are formed under the influence of physical forces such as electrostatic interactions, hydrogen bonding, and chain entanglement [194]. Physically prepared hydrogels are prepared in the absence of chemical cross-linking agents. They are readily degradable and can be used extensively used in the biomedical field. These materials are characterized by good degradability and thixotropy. Physical hydrogels can be converted to solutions when heated; therefore, these are also known as pseudogels or thermally reversible gels [195]. The PVA hydrogel obtained following the repeated freezing-thawing process is a physical hydrogel. The distribution of the PVA molecular chain in the homogeneous aqueous solution of PVA is highly disordered. The mutual contact between the chains is limited, and this makes the formation of cross-links difficult [196]. The freezing process helps freeze the movement of the PVA molecular chains for a moment. This helps increase the contact time. The van der Waals forces and hydrogen bonds are exploited to form tightly bound local physical cross-linking points. The repeated freezing-thawing process results in the formation of a plurality of physical cross-linking points in the PVA hydrogel. Heating destroys the physical cross-linking point between the molecules, and the PVA molecular chains revert to the disordered state. The hydrogel changes to the liquid state under these conditions. The heating method is one of the most common methods used for the preparation of thermosensitive polymer gels. Xu et al. prepared self-assembled graphene hydrogels (SGH) by heating aqueous dispersions of GO in a Teflon-lined autoclave. The samples were heated at 180 °C for 12 h [197]. The SGH obtained following this method is characterized by excellent mechanical strength and thixotropy. It can be easily prepared. It is noteworthy that the high-heat reaction is hazardous. Electrostatic interactions can stabilize hydrogel networks. Metal cations (Ca2+, Mg2+, and Fe3+) can interact with negatively charged polysaccharide carboxylate groups to form tight networks. This results in the generation of mechanically sound metal-polysaccharide hydrogels. Polysaccharide polymers capable of forming cross-linked hydrogels with metal ions include chitosan [19, 198], pectin [199], and cellulose [200]. The hemostatic effect of the polysaccharide moieties helps maintain moisture in wounds and promotes the process of wound healing. The physical methods used to prepare hydrogels are reversible, and the hydrogels are formed under mild conditions. It has been observed that the stability and mechanical strength of such hydrogels are poorer than those of the hydrogels prepared following other methods.

Hydrogels prepared following chemical methods (for example, those prepared in the presence of cross-linking agents or those synthesized by accelerating the reaction of functional groups in polymer chains) present a stable structure. These are widely used in the field of biomedicine [113]. PVA-based hydrogels can be synthesized using cross-linking agents and following the freezing-thawing method described in the previous section. The addition of glutaraldehyde to the aqueous solution of PVA induces the alcohol-formaldehyde condensation reaction that results in the cross-linking of PVA to form a network of polymer hydrogels [201]. Such cross-linking agents are integrated into the hydrogel cross-linking network. The use of a type of zero-length cross-linker allows the formation of covalent bonds between polymer chains. Integration of the system into the hydrogel network is avoided under these conditions. For example, 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) can react with a carboxylic acid group on the polymer chain to form an o-acyl isourea unit. Urea is formed as the by-product, and it is subsequently released when a primary amine attacks the reactive ester intermediate on the adjacent polymer chain. The reaction results in the formation of a hydrogel network that is stabilized by covalent amide crosslinks [202]. Such cross-linking agents are primarily used to prepare gelatin- [203], collagen- [202], and fibrin-based hydrogels. The mixing of nanoparticles and polymers induced the formation of hydrogel cross-linked networks. The interaction between hydrophobically modified carboxymethylcellulose-based polymer chains and polystyrene or PEG-based nanoparticle surfaces facilitates the formation of polymer-nanoparticle hydrogel networks. The reversible hydrophobic forces under action allow the hydrogel to flow under the influence of the applied shear stress. When the stress is relaxed, the hydrogel regains its original properties [204]. The hydrogel produced from the nanoparticle blend can be effectively used for drug delivery, and it is currently used for the treatment of subcutaneous melanoma in a mouse model [205]. Some enzymes facilitate the hydrogel cross-linking reaction. Transglutaminase catalyzes the formation of isopeptide bonds between lysine and glutamine side chain amides. This reaction can be used to produce intermolecular crosslinks between soluble fibrinogen molecules, resulting in the formation of fibrinogen- and fibrin-based hydrogels [206]. Lysyl oxidase, a copper-dependent enzyme associated with the formation of collagen fibrils, allows the formation of aldehydes from lysine side chain residues under conditions of enzymatic reduction that is followed by the process of interpeptide cross-linking (such as Schiff base reaction). The process results in the production of covalent hydrogels [207]. UV light triggers the process of gelation through the action of photoinitiator molecules which absorb radiation and form substances that can mediate polymerization reactions [208]. The photo-initiator is irradiated by UV light, and this results in the formation of free radicals which attack the vinyl group. Under these conditions vinyl free radicals are formed and the polymerization of the vinyl group proceeds under conditions of free radical polymerization. Therefore, most of the base materials commonly used to prepare photo-cross-linked hydrogels are vinyl-functionalized polymers, such as PEGDA [209], gelatin methacrylate (GelMA) [210], and methacrylated HA (HAMA) [211]. The cross-linked network of hydrogels formed in the presence of photo-initiators is uncontrolled, and heterogeneous networks are produced under these conditions.

Hydrogel, as a hemostatic material, adheres strongly to tissues and can be used to treat wounds with high blood flow. The Schiff base reaction is a nucleophilic addition reaction between primary amine-bearing compounds and carbonyl-containing aldehydes and ketones [212]. The adhesive formed from cross-linked hydrogels produced following the Schiff base reaction presents a network-like structure that is characterized by a high degree of porosity and water content. These materials are biocompatible and readily bind to tissues. The adhesive strength of the hydrogel is high, and the material can be potentially used to heal wounds [213]. Yu et al. attached O-nitrobenzyl alcohol (NB) units (modified under photosensitive conditions) to the backbone of water-soluble carboxymethyl chitosan (CMC), exploiting amide bonds to synthesize the NB-CMC composite. Under conditions of UV irradiation, the NB units in the NB-CMC composite were converted to the O-nitrosobenzaldehyde group, and the formaldehyde group reacted with the amino group in CMC to form a stable cross-linked network. Photoluminescent aldehydes react with amino groups present on the tissue surface to form covalent bonds at the hydrogel-tissue interface. Rapid tissue integration is achieved under these conditions, the adhesive strength realized is high. Experimental results revealed that the adhesive strength of the composite hydrogels is significantly higher than that of commercially available bioadhesives used in clinical practice. The former exhibits excellent blood cell adhesion and coagulation ability and can be used to exert excellent hemostatic effects in vitro and in vivo [20]. The multifunctional bioadhesive hydrogels (containing carboxymethyl chitosan (CMCS), sodium alginate (SA), and tannic acid (TA)) prepared exploiting dynamic covalent bonds (borate ester bonds and Schiff base bonds) helped optimize the mechanical, antibacterial, and antioxidant properties of the hydrogels. The improved adhesion ability of the material was obtained using a rabbit liver hemorrhage model [214] (Figure 2). Gelatin hydrogels are cross-linked via amide bonds, and the cross-linking process usually proceeds following the EDC-based coupling method. The amide bond is formed between the primary amine and the carboxylic acid group on the side chain of the adjacent gelatin chain. Ya et al. introduced cyclized succinate groups into a tetra-PEG hydrogel. The residual butadiimide active ester in the compound could react with the amino group in the tissue to form stable amide bonds. This helped to seal the wounds and control bleeding [99] effectively. Experimental results revealed that the tetra-PEG hydrogel could withstand pressures of ≤294 ± 27 mmHg, and the material exerted significantly high levels of hemostatic effects on a porcine spleen hemorrhage model. The challenges lay in removing the hydrogels that exhibited strong adhesion properties.

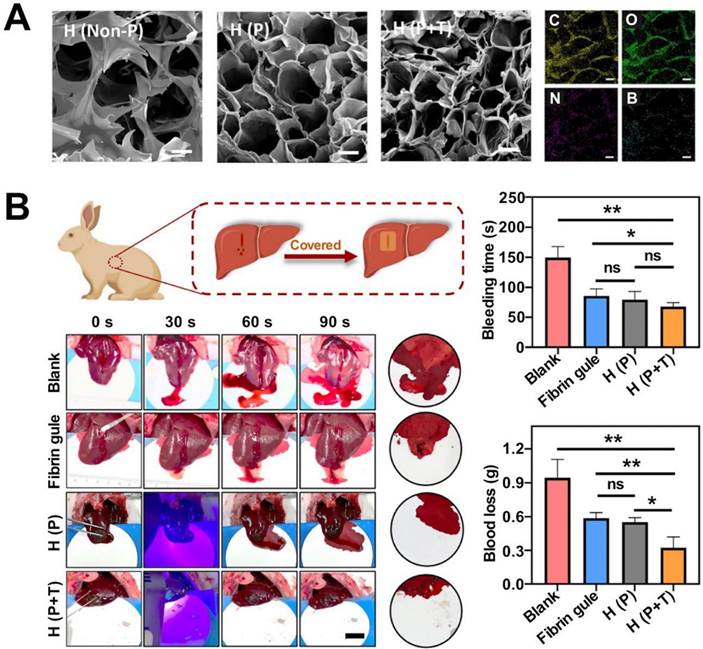

Multifunctional biohydrogels based on carboxymethyl chitosan, sodium alginate and tannic acid and its application in rabbit liver injury model. A: scanning electron microscope images of hydrogels and elemental distribution of C, N, O and B; B: Schematic diagram of the application of hydrogel in a rabbit liver hemorrhage model, including photos of the hemostatic process, comparison of bleeding time and blood loss. Reproduced with permission from [214]. © 2022 Zou Chen-Yu et al.

Hydrogels are a popular form of hemostatic material. The residual aldehyde group on the surface of hydrogels prepared following the Schiff base reaction is potentially cytotoxic, and the strong adhesion ability of the hydrogel makes the safe removal (without causing pain to the patient) of the hydrogels challenging.

Aerogels

Aerogel is a nanoscale porous solid material formed by replacing the liquid phase in the gel with gas following a drying method. Aerogel is the least dense solid in the world and is characterized by high porosity, specific surface area, and adsorption power. Aerogel accelerates hemostasis by absorbing local water from wounds. The porous structure of the aerogel and an increase in the concentration of clotting factors and platelets promote water absorption. A substrate for clot attachment is formed when the aerogel comes in contact with blood. Aerogels can be classified into three categories based on the backbone constituents: inorganic aerogels, organic aerogels, and carbon aerogels.